AWAGAMI

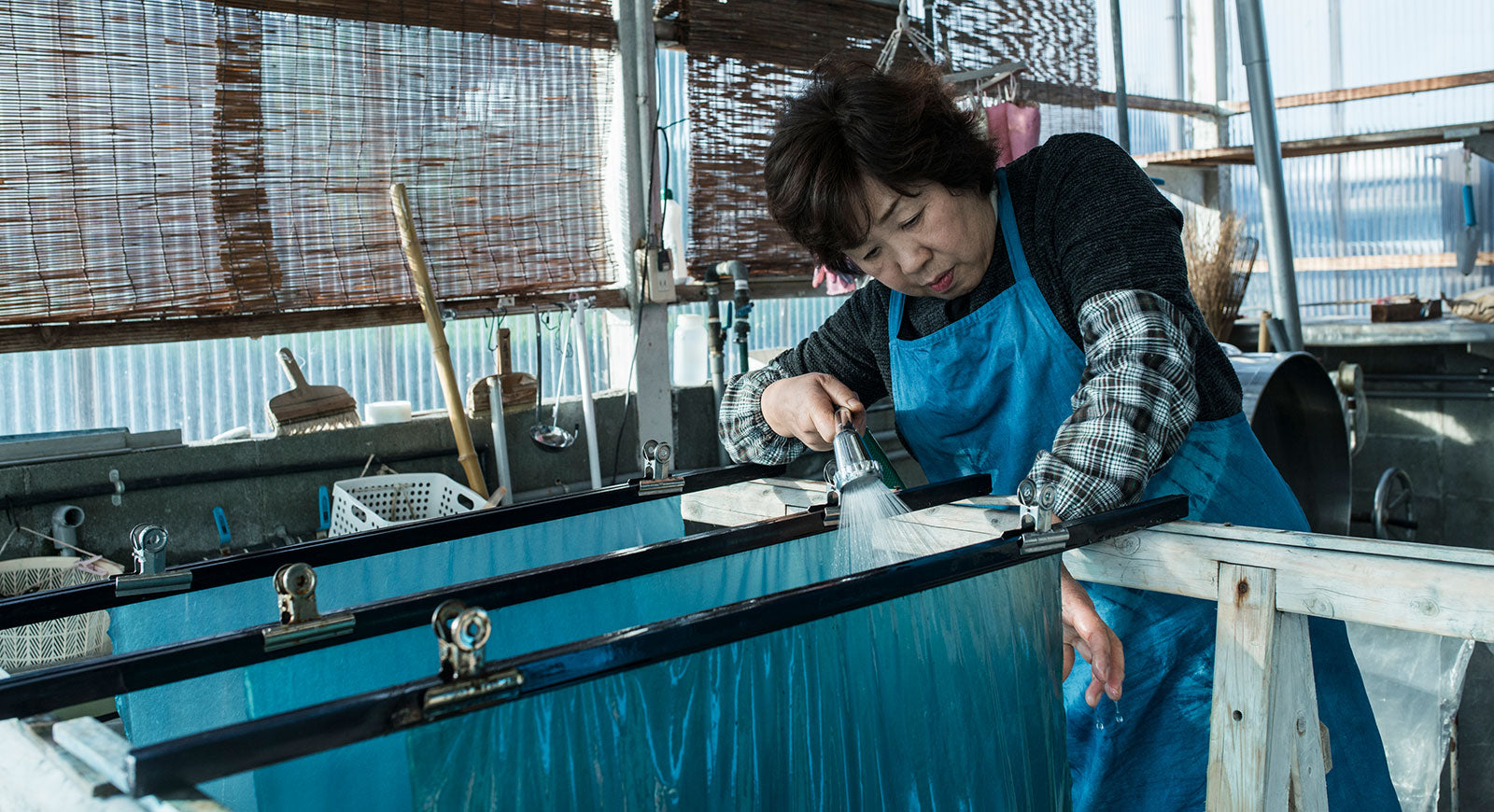

WASHI

for PHOTOGRAPHERS, FINE ARTISTS and DESIGNERS

The Awagami Factory online store offers washi paper & related washi products for our growing international customer base. In order for artists to create their best work, it’s important they choose the right materials.

FEATURED PRODUCTS

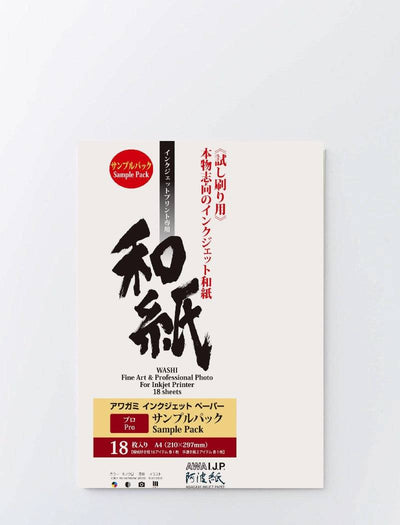

'AIJP' INKJET PAPERS

Awagami Inkjet Papers are revolutionary Japanese washi papers created for the highest quality digital inkjet prints. These impressive papers (suitable for photographers, artists & designers) are made with natural fibers + pure mountain water-insuring museum quality archival prints. AIJP papers faithfully retain the unique texture of Japanese washi yet have been specially coated at our mill to maximize the creative potential of your digital print experience.

FINE ART PAPERS

Awagami Fine Art Papers are crafted exclusively in Tokushima with the artistry and knowledge gained from 8 generations of papermaking. These papers are made with A+ rated natural fibers to yield sheets of expressive surface and impressive character. Awagami Fine Art Papers are acid-free and made with respect and care for professional artists and students alike. Here you will find papers suitable for painting, drawing, printmaking, book arts, crafting and alternative photography.

HOBBY PAPERS + KITS

Awagami makes a variety of decorative paper sets and interactive kits to spark your creative potential. Enjoy origami, scrapbooking and paper crafts or try your hand at traditional Japanese paper dyeing and papermaking.

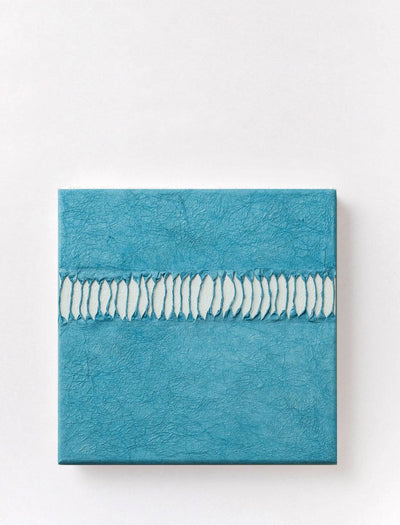

STATIONERY, DÉCOR & GIFTS

Awagami’s famed indigo (“Aizome”) papers are used for a variety of our handmade notebooks, stationery, desk accessories and limited-edition art panels. A wonderful assortment of items for true paper aficionados may now be purchased for the first time online…Check on our Awagami branded merchandise here too.